Fuel and Combustion Characteristics

Fuel properties

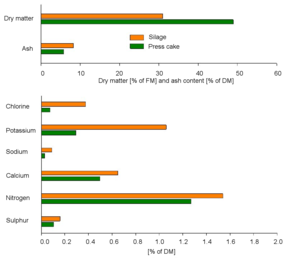

The separation of the biomass (silage) into a liquid (press fluid) and a solid part (press cake) considerably improves the fuel properties of the latter. This could be verified for the conditions of different European regions and their respective grassland types.

The content of detrimental minerals like sulphur, chlorine, potassium and magnesium is considerably reduced. The nitrogen content is slightly reduced as well. The reduced fraction of sulphur and potassium lowers the corrosion risk.

The mineral content of the fuel is lowest if the primary biomass is grass rich and harvested late in the year.

Combustion technique

The elution of potassium from the feedstock is especially important, as this leads to a significant upgrading of the fuel in terms of the ash softening behaviour. The softening temperature of the dehydrated grassland fuel is up to 1100 °C and is therefore within the range of typical wood fuels. An ash softening temperature of this magnitude is essential in order to facilitate the low-maintenance and failure-free operation of biomass boilers.

Whereas mashing and mechanical separation of the grassland biomass (IFBB technique) reduces the content of detrimental minerals to the level of firewood, the still high ratio of nitrogen requires an adjusted combustion process. However, with the use of staged combustion burners the emission of nitrogen oxides is low and the limits of the relevant anti-pollution regulations can be observed.