Engergy and Greenhouse Gas Balance

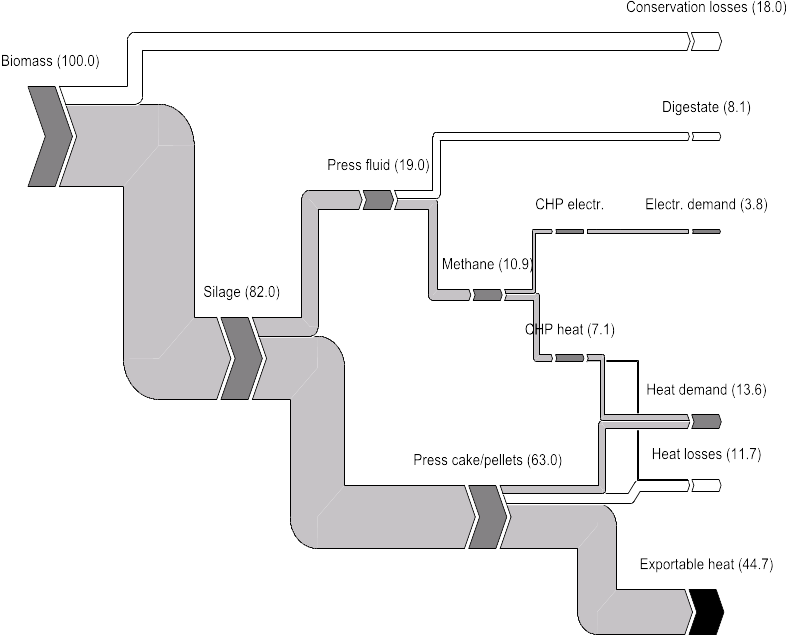

With the PROGRASS® approach previously unused grassland biomass is converted to energy by the IFBB technique. As sketched in the adjacent figure, about 45% of the energy stored in the biomass are transformed into exportable heat.

If the IFBB plant is constructed as an add-on to an existing biogas plant, the waste heat of the biogas plant can be utilized for drying the press cake. This enhances the energy efficiency to about 53%.

The biogas gain by fermentation of the press fluid meets the additional electricity demand of the IFBB technology. Even, if the fuel consumption for transport and mowing is included, the energy balance remains positive.

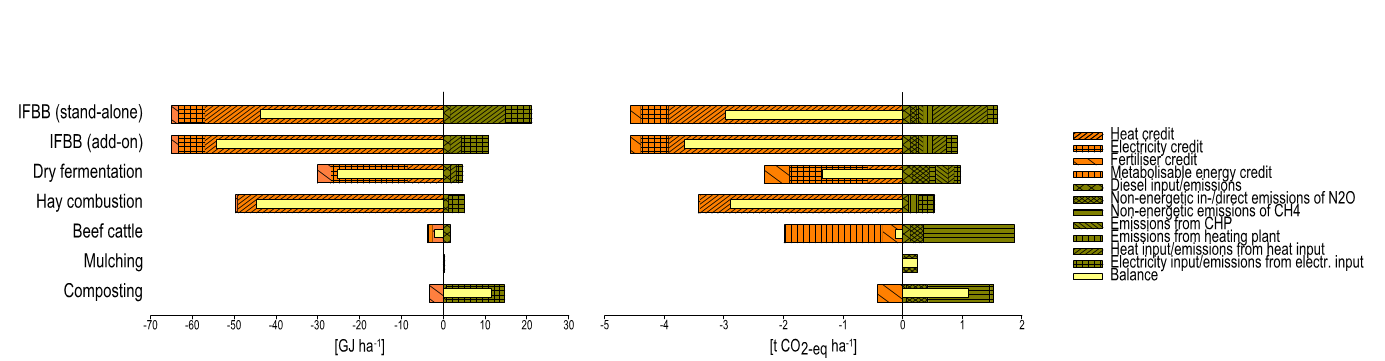

The next figure displays an analysis of the energy and greenhouse gas balances that are attained by different IFBB related systems. It demonstrates that the highest potential savings of fossil fuel and greenhouse gas emissions are obtained in an integrated system where the IFBB-technique is combined with a biogas plant (IFBB-add-on).

An independent IFBB-plant (IFBB stand-alone) and hay combustion exhibit similar energy and greenhouse gas balances, but not as favourable as an IFFB-add-on. The exclusive biogas recovery by dry fermentation offers the lowest saving potentials because of the minor digestibility of the green-cut of semi-natural grasslands.

harvesting biomass

processed biomass

"We want to establish a local circular flow. Currently we are producing an equivalent of 2.5 million litres of fuel oil. We are reducing a relativly high amount of CO2. That equals 10.000 tons of carbon dioxide."

Bernd Schäfer

"Compared to the gross consumption of the city that means five percent we can contribute. That isn't really a high amount, but the question is, how can we use the wastes? In which way? Environmentally safe, if possible. Anything we sell as fuel, we don't need to spend on fossil fuel as fuel oil or natural gasoline."